Overhead Crane

Unexpected shutdowns are costly and very demanding for the workforce involved. Make your overhead or (semi) gantry crane smart in order to increase its availability and avoid incidents.

To determine when a maintenance intervention is required, today most often technical data sheets are coupled with the knowledge of a number of unique experienced individuals. Repairs are done when it's already far too late. All of this puts tremendous strain on the people responsible for maintaining the overhead crane, while it can be avoided, quite easily.

The only way to validate the actual health is by automatically having a continuous look at a broad data set and adding a specific multi-aspect monitoring setup consisting of different sensor types that follow the behaviour of the cranes general state-of-health: a smart (overhead) crane monitoring system.

We understand the problems you face

Catch them before they cause greater damage!

Guide wheel damage

Premature ageing or damage to the rails are causing multiple headaches. Smart monitoring solutions allow detecting excessive guide wheel sollicitation and provide routes to reduce them to a minimum.

Rail degradation

No manipulations without a healthy rail. Smart combination of data sets allows detecting weak spots in the rail or support structure prior to damage: cracks can be prevented and repairs can be done early and kept short.

Hoisting system health

The key element of an overhead crane is the hoisting system. Consisting most often of a (set of) motor(s), a gearbox, drum(s) together with bearings this entire drive train needs to remain in top shape for the crane to be able to perform its primary function. All of these components can fail or wear down. Smart monitoring can help to avoid excessive damage and allow you to plan in interventions.

Fatigue, structural deformation, cracks, and lifetime extension

Overhead cranes often are stretched to their limits. A dedicated follow-up helps in assessing if the structural integrity is getting compromised or not.

Gearbox health overview

A loose gearbox, damaged teeth on the main translation gearbox: all lead to long repairs and unavailability. A continuous follow-up based on the crane’s operating condition allows to generate early warnings and prevent excessive damage.

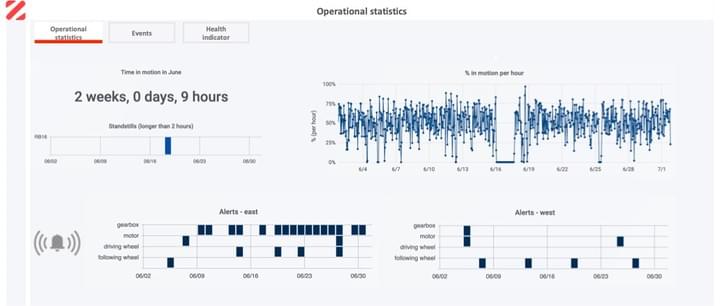

Operational Statistics

Availability and efficiency are not always know for such large assets. By tweaking the recorded data just a bit more, insightful statistics can be generated that allow getting a better grip on the state-of-affairs.

AXLE ALIGNMENT | MOTOR HEALTH | BOLT TENSION | CABLE DAMAGE | BUFFERS | SUPPORT STRUCTURE INTEGRITY | STEEL CRACKS | DRUM HEALTH AND COUPLINGS | BREAK USAGE | BEARING HEALTH

Compatibility

Our Overhead Crane monitoring products are compatible with the following brands:

- Kone Cranes

- Femont

- Demag

- Terex

- Bertolotti

- Donati

- Jaso

- ACA

- ...

Software integrations

All of Zensor's products are compatible with standard CMMS or EAM software. Connections can be set up to source the most recent interventions and changes on the asset, or to create a ticket when an intervention is required on an overhead crane. Compatible with:

- IBM Maximo

- IFS Ultimo

- eMaint CMMS

- iba

- Aveva

- SAP

- ...

Solutions

Learn more about our approach

Performance

Based on the data collected and machine-learning based methods for determining the operational condition the performance is calculated.Quality

Coupling to existing databases or using human input fields the product quality is linked to operational process parameters.Warnings

Whenever values start to deviate, or data streams stop, warnings are sent. This avoids 'black holes' in the insights of the production line or assets.Increase availability

Have a continuous idea of availability, automatically as the platform combines different input streams and contextual information.

Operational statistics

Know what your overhead crane is doing all day every day

Health status

Know how much your crane has lifted, how far it has travelled and how many hours it has been active - does it meet your expectations?

Event and alerts

Know where the latest events have happened - can you see a trend?

Our Experiences

Projects we worked on:

Projects we worked on:ArcelorMittal

Belgium

We're helping ArcelorMittal to monitor the structural integrity of their bolts on the buffers of the critical gantry cranes in the production site of Gent.

One-pager:

One-pager:Specific one pager

We know your greatest problems when working with a critical asset such as an overhead gantry crane. Learn more with the free download.

Blog post:

Blog post:Experience at Hüttentag

Last week Zensor attended the Hüttentag in Essen. During this annual event the entire German steel industry meets up to discuss the state of affairs and exchange ideas about upcoming developments and changes...

Looking for another asset?

Zensor NV

BE0537837878

© 2025